Pros and Cons of Manifold Water Filtration Systems

Residential reverse osmosis (RO) water filters have been on the market for over thirty years. They have become the go-to filtration system for drinking water, as they can be used with nearly any water source.

A wide variety of RO filter systems are available due to the improvements made in the design and function of RO systems over the years. You can choose systems that provide the basic filtration functions, as well as higher-end systems that are convenient to use, provide multiple added functions, and are elegantly designed to match home or restaurant décor.

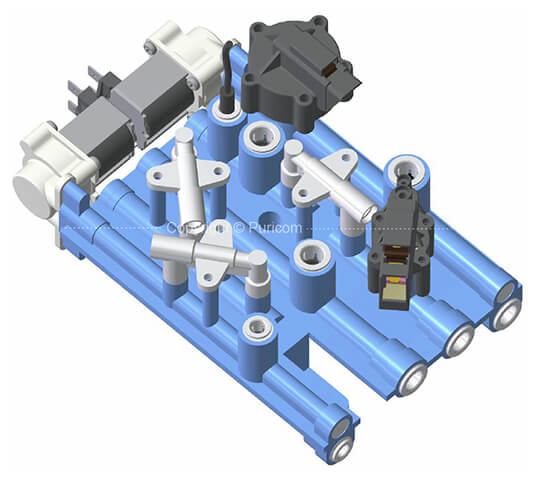

With RO becoming ever more popular, more focus has been placed on streamlining production and cutting manufacturing costs. As anyone who has seen an RO system knows, it usually has a lot of tubes and connectors connecting the various components and stages of filters. To reduce a large number of fittings and tubing required for an RO system, some of the larger filter manufacturers have started to design systems that combine into one panel, many of the individual tubes and connectors required in an RO system. These panels are called manifolds.

The Manifold Filtration System - How it Works

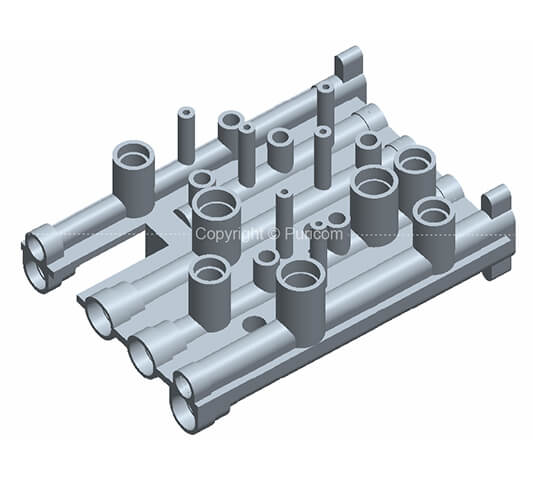

A manifold waterway system is a solid, one-piece board or panel that is formed by plastic injection, with multiple channels integrated within the board. Multiple valves and filter elements can be connected to this one board. Due to manufacturing constraints, the channels will usually be laid out either vertically or horizontally, and all at 90-degree angles to each other.

Two methods of manifold construction presently being used are one-piece injection molding, where the manifold is injected in one step, and split-integrated channel molding, where an upper and lower panel are formed separately and then welded together.

The split manifold method is more flexible, but it has higher requirements for the welding process and leaves visible welding lines. Currently, the most popular method used for welding is ultrasonic welding. Ultrasonic welding uses high-frequency vibration and pressure to melt and bond the plastic panels together. The one drawback is that the pressure-bearing capacity and overall strength of the welded manifold are not as good as that of a single injection manifold.

Advantages and Disadvantages

Manifold systems have some advantages and some disadvantages compared to traditionally constructed systems. How you look at these will depend on whether you are the manufacturer, the installer, or the user. So, let's look at each separately.

For the User

One of the advantages of a manifold system is its solid construction. Also, because they have fewer fittings and connectors, they are less prone to leaking. They are also usually more esthetically pleasing and compact, so look nice and are appropriate for smaller living spaces.

Replacement filter elements are usually designed for easy installation, so may even be able to be replaced DIY by the users, reducing the need to call for filter replacement services.

The downside is, these replacement filters are usually more expensive. They sometimes combine two filter functions into one cartridge, which means fewer cartridges to change, but they need to be changed more frequently.

From the Side of Manufacturers

From the beginning, the main focus of designing a manifold system was to reduce cost by manufacturing in large volumes. While the initial investment cost for R&D and mold production is very high, if they can be mass-produced as a single unit, they can cut costs in components, and the labor required to assemble the units.

If the manifold’s design is simple enough for automated production, it can be produced and assembled by robots.

However, the huge costs associated with the development and production of these integrated systems pretty much exclude the possibility of small companies from developing them. The manufacturers' R&D team needs to be strong, and the highly advanced equipment needed for production is expensive.

From the Side of Dealers - Installation and Maintenance

Manifold systems are usually very simple and convenient to install, and replacing the filter cartridges is easy. They are often equipped with integrated snap-on or quick-change filter elements. Some have an automatic water lock function, so filters can be replaced without the need to cut off the water source.

Generally, the five-stage filtration elements that you find in a traditional RO system will be combined into two or three cartridges, each having multiple filtration layers. This makes filter changing easier, but the lifetime of the filter element is shorter, so filters need to be replaced more frequently. In areas with poor-quality inlet water, this problem will be more serious.

Conclusion

While manifold water purifiers show promise for the future, they are still in the development stage. However, there are advanced manifold systems on the market that may have just the right features to meet your need.

Due to the higher technical nature of manifold filters, until the market becomes more mature, it may be advisable to buy a reputable name-brand product or a product from a niche brand manufacturer that specializes in the water purification industry.